Reframing Manufacturing Collaboration

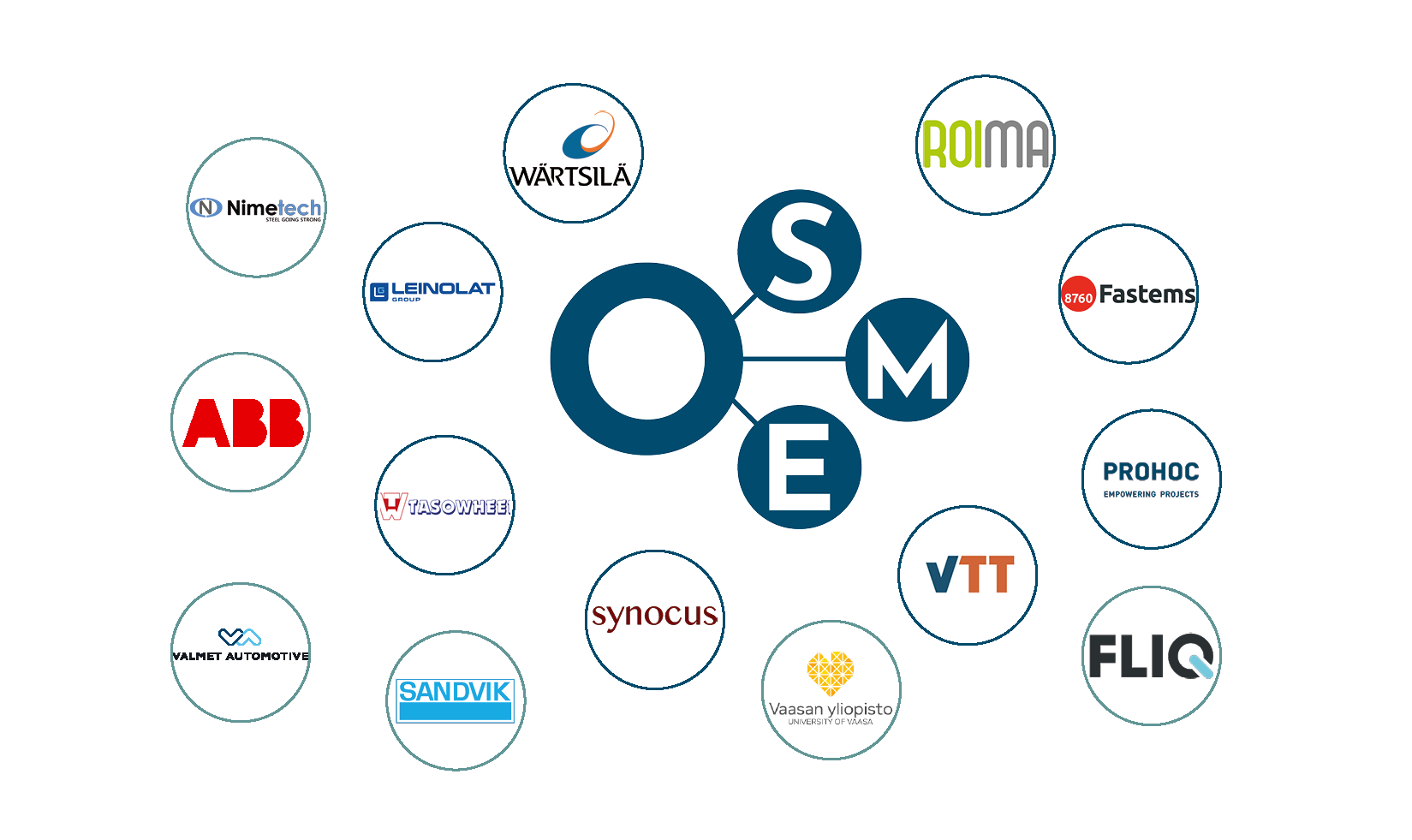

Today manufacturing faces a moment of unprecedented change. Lead times are getting shorter, and resilience is the new buzzword. Quality requirements are more stringent, and manufacturers have become responsible for traceability strengthening the ties between suppliers and principals. Due to climate change, companies must comply with increasing environmental restrictions and there is an ongoing dialogue between manufacturers and policymakers on how to make manufacturing more sustainable. To be attractive to top talent manufacturing is forced to open up and engage in the broader issues relating to their purpose and mission. To address these challenges Open Smart Manufacturing Ecosystems, OSME, is a collaborative initiative that engages leading manufacturing companies to speed up the needed transformation.

OSME originates from Wärtsilä in Vaasa that recognized that when moving the factory from downtown to Vaskiluoto it could reframe its manufacturing concept. This created the idea of the Smart Technology Hub, which sees Wärtsilä as an extended enterprise. OSME engages, supports, and leverages upon the skills and strengths of its partners. OSME can adapt and learn based upon the insights evolving through the collaboration.

Open

In manufacturing openness means that we share with others what we want, not based on predefined rules that everything must be shared like in open-source software. As individuals, we know that the most important thing in sharing is trust. And trust must be built over time. So the OSME members build their collaboration based on trust.

Smart

To be smart we focus on doing things and learning as we go. Activities and events shape how we proceed. This is what we mean by smartness in OSME. We live in a world that is constantly changing. Therefore OSME members must continuously consider alternative scenarios, evaluate new situations as they emerge, and move forward with an open and learning mindset.

Manufacturing

Finland is one of the most manufacturing-intensive countries in Europe. We build on this strength and want to drive the transformation of manufacturing towards improved sustainability and efficiency with the help of digitalization. OSME is supported by Business Finland, and through our strong cooperation with the MEX Finland network, we expect to be around for years.

Ecosystems

We have learned from Finnish ecosystems such as NMT, Linux, and the Finnish gaming sector that success comes from committed individuals with a strong purpose beyond making money. In OSME we want to motivate and engage individuals for a broader responsibility than what they have in their own organizations. We want to be the world’s most inspiring community for manufacturing professionals.

Towards Open Smart Manufacturing Ecosystems 2.0

OSME is the collaboration platform for Wärtsilä’s extended enterprise and, as we approach the end of our first phase, it will now be shared with others. The aim of OSME is to enable stronger integration between principals and suppliers in manufacturing ecosystems.

OSME contributes immediate operational benefits for the partners, but it also aims at longer-term strategic impact in the society. To achieve these objectives we must conduct both breakthrough conceptual research and apply new theories and technologies in real-world experimentation and proof of concepts.

Today, we are inviting new members to join OSME and expand the ecosystem, creating OSME 2.0. For more information see our newsletter.

OSME Showcases

OSME is enabling a shift from a traditional linear value stream to a more resilient, collaborative network that is based on a digital foundation. By sharing Use Cases we can increase understanding of improvement areas and foster proactive planning of activities resulting in reduced lead times, traceability and feedback loops, optimized logistics, and better quality with less effort. This method also allows us to build competences together through concrete learnings and shared understanding of each other’s challenges by sharing data and information.

In this collection highlights our manufacturing ecosystem collaboration in action – take a look what collaboration can achieve.

OSME Integrating Performance and Transformation

To address present challenges the OSME initiators are united by their ambition to make manufacturing both more creative and more productive. This will ask for a totally new way of working together that the OSME initiators will co-create and use both for their own benefits and contribute to a more responsible and sustainable manufacturing paradigm. Each of the initiators brings a complementary capability to the collaboration.

Wärtsilä wants to develop an integrated smart manufacturing ecosystem where knowledge, capabilities, technology, systems, and solutions to common problems can be shared. This will result in a more resilient value chain based on distributed manufacturing as a differentiator. Wärtsilä and its partners will adapt and innovate to market needs and lead the decarbonization roadmap in the marine and energy industry.

VTT provides key enabling technologies in federated data spaces such as IDS to be taken into use in implementing the data architecture of OSME. The implementation of IDS components supports the implementation of OSME pilots and enables an open self-sustainable manufacturing ecosystem.

Roima Intelligence contributes to the Open Smart Manufacturing Ecosystems digital platform through the integration layer and additional proof of concepts. This will provide users with operational transparency, quality monitoring, and sustainability.

Fastems contributes to Open Smart Manufacturing Ecosystems by creating specifications and proof of concepts for factory-level manufacturing cockpit solutions integrating shop floor machinery to collect and share data. This will allow advanced and real-time management of production.

Tasowheel identifies the different types of resilience requirements of the participating companies (multi-site manufacturing models, alternative sourcing models, redundancies in bottlenecks, etc.) to develop an actionable framework for manufacturing resilience.

Prohoc develops new support tools for human-centric operations. This will be done by building a model that enables inspired self-organization within the ecosystem and an environment where operators are seen as value creators.

Leinolat Group supports OSME with experience on how manufacturability and total-cost optimization should be considered already in the engineering, design phase and throughout the product lifecycle through digitalization and 3D design.

Synocus co-orchestrates the OSME community to strengthen the collaboration among the ecosystem members through continuous capability-building efforts improving quality, shortening throughput time, and supporting innovativeness to reduce costs and increase value for customers.

In addition to the initiators, the OSME collaboration also comprises a growing number of Associate Partners that will provide additional strengths to the OSME network. The first Associate Partners are ABB, Fliq, Nimetech, Sandvik, Valmet Automotive, and the University of Vaasa.

For more on OSME, please contact

Christian Sundman

Wärtsilä

christian.sundman(a)wartsila.com

Niklas Koski

Synocus

niklas.koski(a)synocus.com